Well-Testing Equipment

- 3-Phase Separator

- MPFM System

- Surge Tank

- Knock Out Drum

- Flare Stack

- Transfer Pump

- Backside Flush/Test Pumping Unit

- SSV

- Sand Filter

- ESD panel

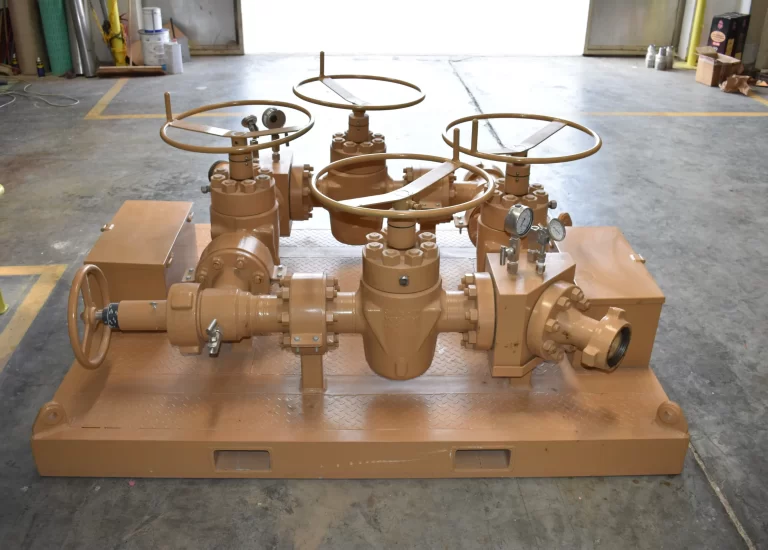

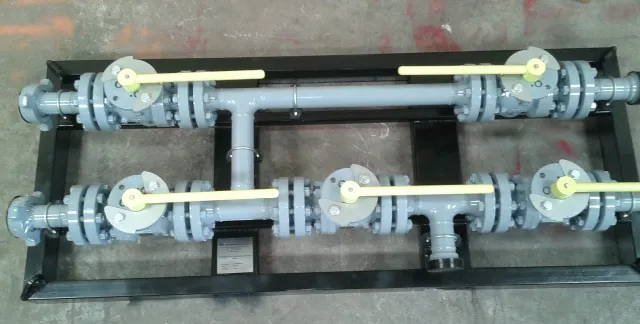

- Choke Manifold

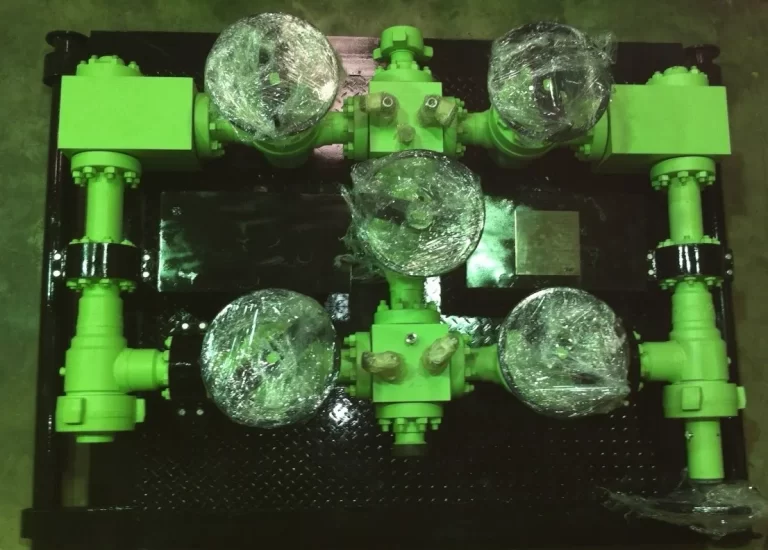

- Diverter Manifolds

- Data Header

- Piping Packages

MSI FZC developed a range a well testing multiphase separators with several pressure ratings available, 250 PSI, 900 PSI, 1440 PSI and 2160 PSI. These multiphase separator pressure vessels are ASME “U” stamped and NACE MR-0175 compliant. There are equipped with Daniel orifice valves, PSV and all usual control valves.

The separators can be skid mounted for onshore and offshore operations (DNV certified skids)

and can also be trailer mounted when integrated in complete well testing trailer systems.

MSI FZC makes complete MPFM systems integrated with piping and manifolds upstream and downstream. The MPFM selected to be integrated into the system can come from various

suppliers (Haimo, Agar, Medeng, ABB, Roxar-Emerson,…) depending on clients’requirements.

The systems can be skid mounted or trailer mounted. Trailers are custom built and are provided with necessary documentation for registration in the country where they are intended to be registered.

The skid mounted units can be made for onshore and offshore operations.

The units can be made for desert and arctic environment and can be CE marked and Gost certified on request

MSI FZC manufactures well testing dual compartment surge tanks of various sizes and pressure ratings to be mounted either on skids or on fully integrated well testing trailers.

The tanks are ASME “U” certified and equipped with hi-lo level sensors/alarms, PSV, liquid level gauges. When mounted on skids the skids can be DNV certified.

MSI FZC knock out drums are designed to remove droplets of liquids carried by gas streams to

go to flare. The separation is made by gravity by slowing down the stream of gas coming from

inlet line. This is achieved by making the stream enter a large chamber (vessel). This and other geometry elements inside the vessel allow the droplets to fall at the bottom of the vessel.

PSV and Hi/Lo sensors and liquid level gauge are installed on the vessel.

The vessel is NACE MR-0175 compliant and ASME “U” stamped and certified. Pressure rating and volume depends and clients’ requirements.

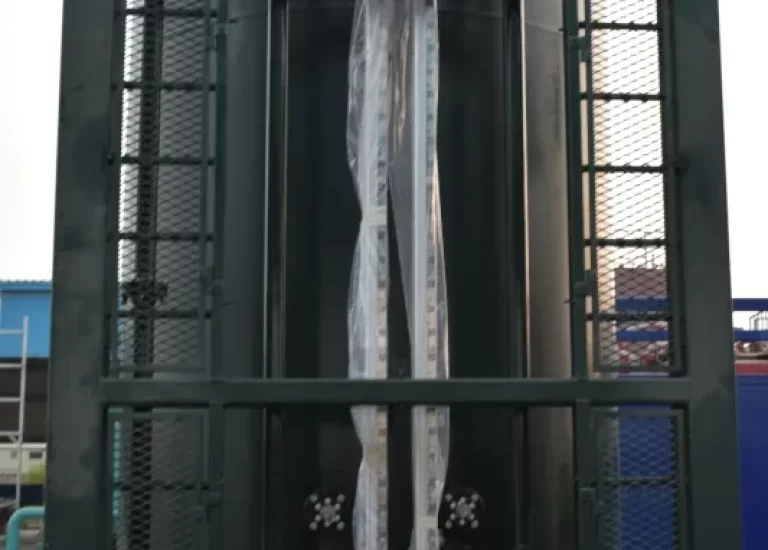

MSI FZC manufactures flare stacks according to the needs of the clients. The flare stacks can be designed for offshore and onshore operations. The capacity of the flare stack and the size is

calculated in accordance with the requirements of the clients.

The onshore stacks can be skid mounted with a pad, cables and concrete anchor blocks or trailer mounted with hydraulic deployment system and stabilizing legs.

The ignition system uses piezo electric spark generator.

The trailer mounted flare stacks are built on custom built trailers coming with all registration documents for the region they are intended to be registered in. They can be CE marked and Gost certified upon request .

Tri-Heads Green burners are also available.

MSI FZC manufactures fluid transfer pumps using a variety of pump types and materials to

comply with the application. As a result depending on the types of fluids to be pumped the

transfer pumps can be made of carbon steel with an internal FRP coating, or they can be

entirely manufactured in Stainless Steel or they can be made on Teflon.

In addition the pumps can be centrifugal type, single stage or multistage, membrane type,

progressive cavity type, reciprocating type….

The pumps can be driven mechanically by diesel engines, electric motors, hydraulic motors,pneumatic motors,…

The diesel engines can be water cooled or air cooled with manual or pneumatic PTO clutches.

The electric motors can be AC or DC, if need be they can be equipped with variable speed

control.

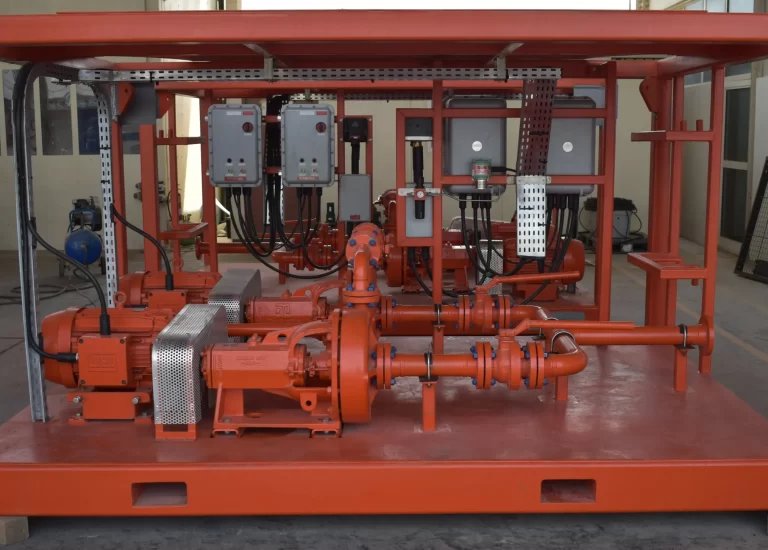

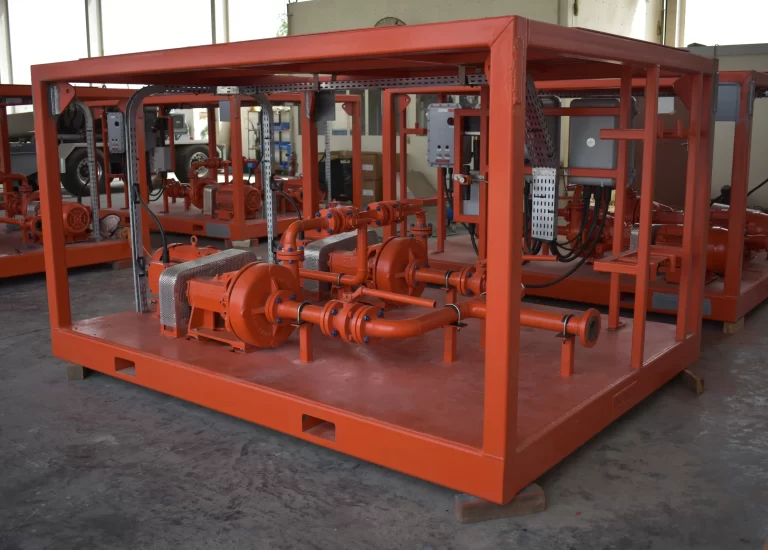

MSI FZC manufactured Flushing/Test pump units used to flush lines/casing and to perform pressure tests of the line and casing. These pumps are typically ranging from 100-180hp and are a reciprocating type. They usually pump water and use that same water as a lubricant too

for the plungers.

They can be equipped with electronic and paper chart recorders.

These units are very compact and can be built on skids or on small trailers that can be pulled by

standard pick-up trucks.

Previous

Next