Fracturing Equipment

- Frac Pumpers

- Frac Transfer Pumps

- Frac Manifold

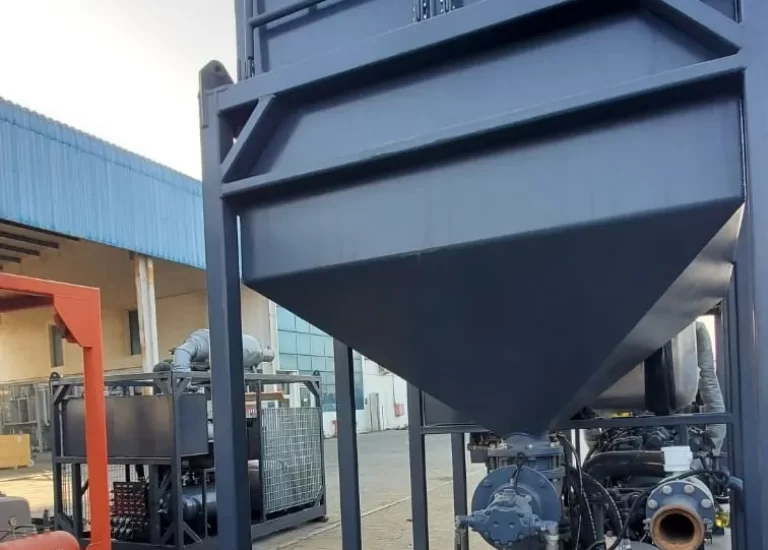

- Frac Sand Silos

- Frac Blender

- Frac Hydration Unit

- Frac LAS

- Frac Data Van

- Frac Tanks

MSI FZC manufactures a variety of Frac Pumpers of up to 3000hp, on skid/trailer/truck suitable for any type of terrain and desert or arctic operations, onshore and offshore. The units can be used as stand alone pumpers or built as a fleet to work together.

The pumps used are as per the requirements of the clients (SPM, Gardner Denver, MSI, Serva,….) as we all the engines (Caterpillar, MTU, Deutz, Cummins, Volvo Penta,…) and the transmissions (Caterpillar, Allison,…).

The pumpers can be CE marked and Gost certified upon request.

he offshore units are built in several modules to comply with the maximum load capacity of the

rig cranes and are DNV certified.

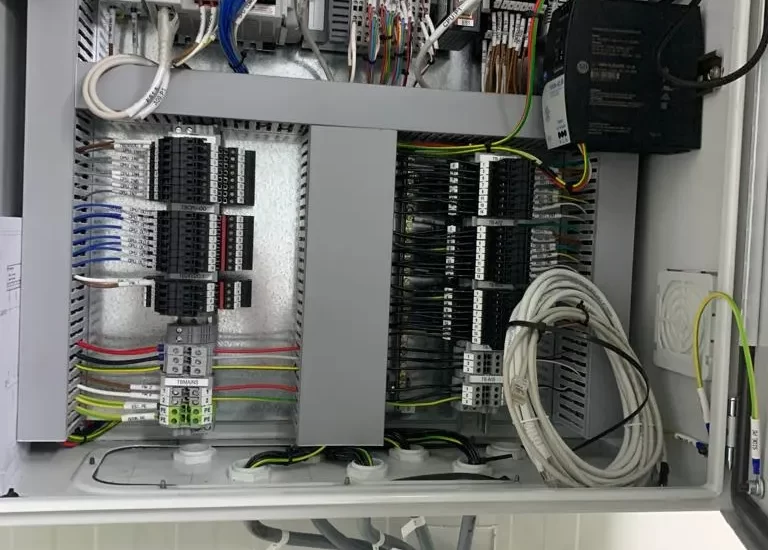

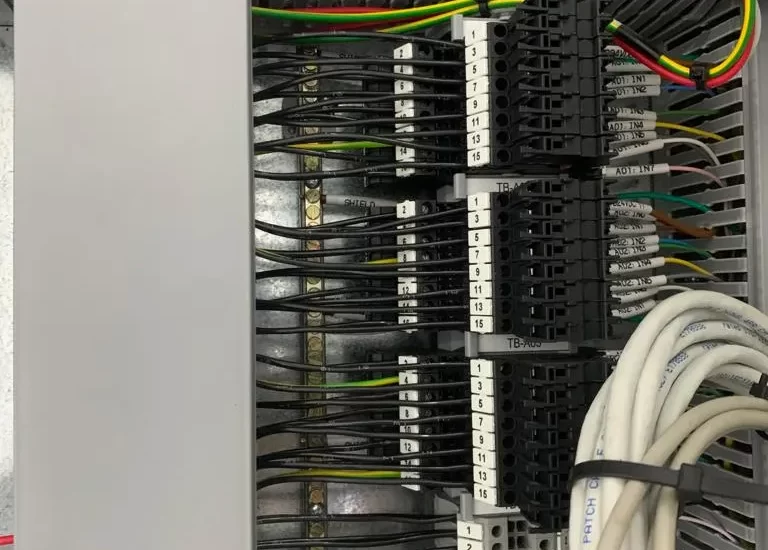

The units are equipped with complete electronic control system which can be connected to a Data Van either by wire or by wifi.

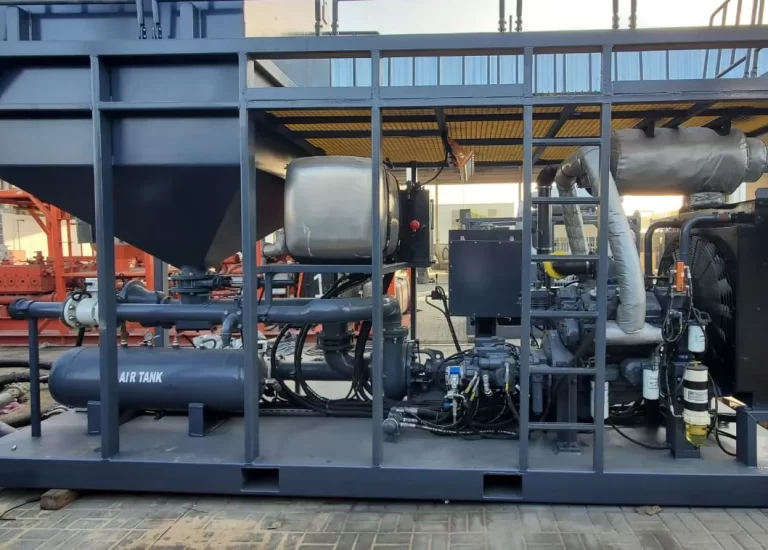

MSI FZC builds Frac Transfer Pumps which can be used to feed frac pumpers by transferring

Frac proppant from the blenders or other supply sources to the pumpers. The Frac Transfer

pumps can be skid mounted or trailer mounted and even truck mounted.

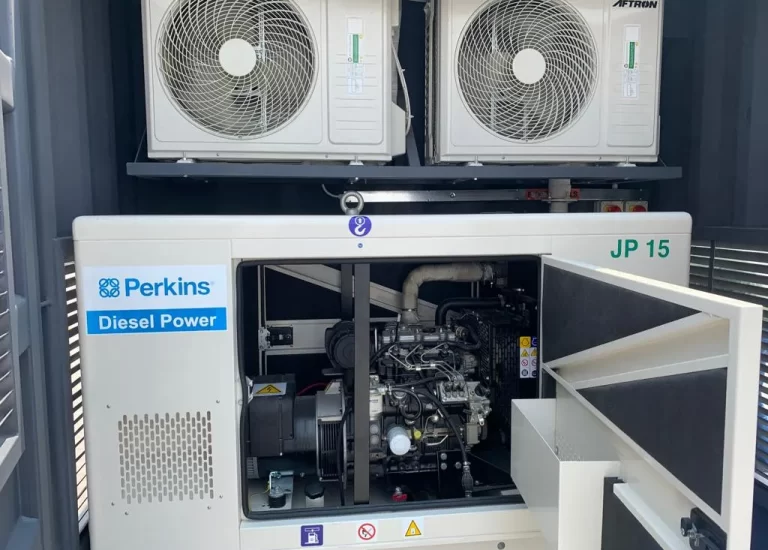

Various brands of electric motors (ABB, WEG, Valiadis,…), diesel engines (Caterpillar, Deutz,

Cummins, Perkins, Detroit Diesel, Volvo Penta,…), hydraulic motors (Denison, Veljan,…) and

C-pumps (Gardner Denver, MCM, NOV, Serva,…) are available to meet the

clients’requirements.

In case of trailers, the trailers are custom made and come with necessary registration

documents for the regions/country where they are intended to be registered. Same applies to

the truck mounted systems.

The units can be CE marked or Gost certified upon request.

MSI FZC manufactures frac manifolds, aslo called missile, on skid, trailer or truck. The manifolds can accommodate up to 20 frac pumpers suction/discharge. The HP discharge lines

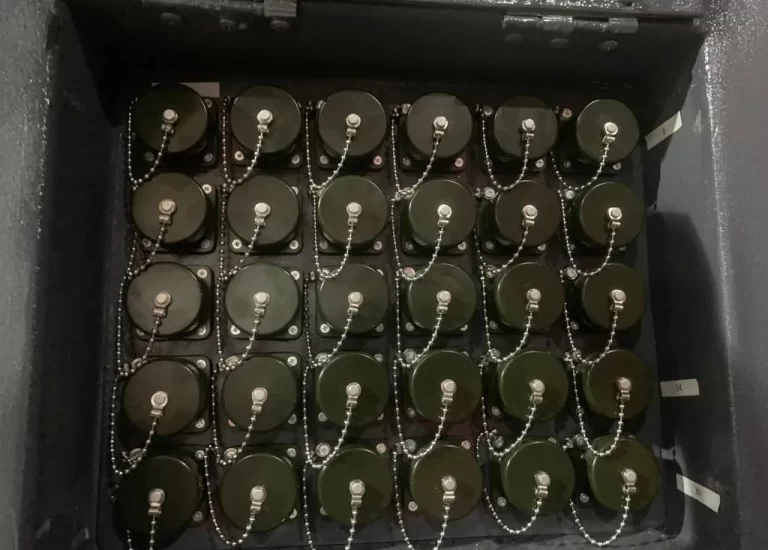

can be either 3” or 4 “and the connections can BE Fig.1502 or Clamp Hubs. All the treating iron

is integral, 15K PSI STD service rated.

The LP manifold provides two (2) suction connections for each frac pumper.

All LP manifold outside connections (Blender/Frac transfer pumps, Frac pumper suctions) are equipped with 4”quarter turn butterfly valves and 4”Fig.206F connections with Fig.207 blind caps.

The LP manifold can be 8”/10”/12” depending on the number of of Frac pumpers to feed.

Addition outlets in HP and LP manifolds are made for bleed off and provision.

In case of trailers, the trailers are custom made and come with necessary registration

documents for the regions/country where they are intended to be registered. Same applies to

the truck mounted systems.

Trucks can be of any brand. Choice of chassis is as per clients’ requirements.

The systems can be CE marked and Gost certified upon request.

Previous

Next