Drilling & Workover Equipment

- Mud Pump package

- Choke & Kill Manifolds

- Mud Manifolds

- Mud Degasser

- Mud Tanks

- Workover Tanks

- Liquid Mud Plant

- Mobile Labs & Workshops

MSI FZC manufactures Mud Pump packages for drilling and workover operations. The mud

pumps can be of any brand (GD, National, Dragon, Bomco, Gaso,….) and can be driven by

either electric drive (GE, Joliet,…), hydraulic drive or mechanical drive (CAT, MTU, Cummins,

Deutz,…).

The mud pumps are equipped with Pulsation Dampener, charging centrifugal pumps and

pressure safety and reset valves.

The units can be built in several modules for easy of transport and lifting for both onshore and

offshore operations.

MSI FZC builds complete Choke & Kill manifolds for drilling operations onshore and offshore. The type of valves and chokes can be selected as per clients’requirements. The pressure ratings, trims, temperature ranges, size and configurations of the manifolds are as per the requirements of the clients.

The manifolds can be equipped with customized MSI FZC made Buffer Chamber and with

hydraulic drilling chokes for which MSI FZC also provides Drilling Choke Control Consoles.

All manifolds are built according to API 16C, all flanges are API 6A monogrammed and pressure

tests are conducted as per API 6A with third party (BV, DNV, Lloyds) witness.

MSI FZC manufactures drilling mud manifolds for operations onshore and offshore. The type of

valves (Demco, Oteco,…) can be selected as per clients’requirements. The pressure ratings, trims, temperature ranges, size and configurations of the manifolds are as per the requirements of the clients.

As these manifolds are welded, the welds are inspected by X-ray and Post Welded Heat Treatment are performed on the welded joints. Full reports from certified third parties are provided to the clients as part of the standard databook provided by MSI FZC.

All pressure tests are conducted as per API 6A with third party (BV, DNV, Lloyds) witness.

MSI FZC manufactures Drilling Mud degassers. These can be of various sizes depending on the drilling/workover operations needs. They are designed as per the clients’requirements.

All degassers are of vertical design and the U-tube can also be designed to complete the installation package.

MSI FZC manufactures Mud Tanks for drilling mud storage and transport.

The tanks can be either skid mounted or axle mounted.

Dimensions of skid mounted tanks match the dimensions of standard 40ft seafreight containers

to avoid extra expenses for shipping of oversized equipment.

The tanks can be designed for various mud densities.

The are equipped with fillup line, recirculation line, discharge line and drain line. Venting system

and liquid level gauges are installed on the tanks. Manholes are installed on the top of the tank and on one side allowing air circulation for the safety of the inspector when both manholes are open.

In addition MSI FZC manufactures mud tanks with open tank and several compartments for the

treatment of the recycled mud and cuttings.

These systems are designed specifically for each project based on the requirements of the client’s operations.

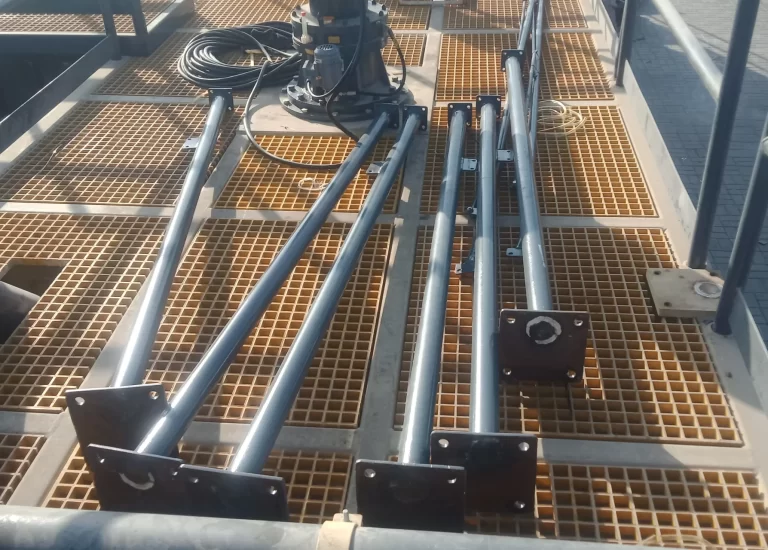

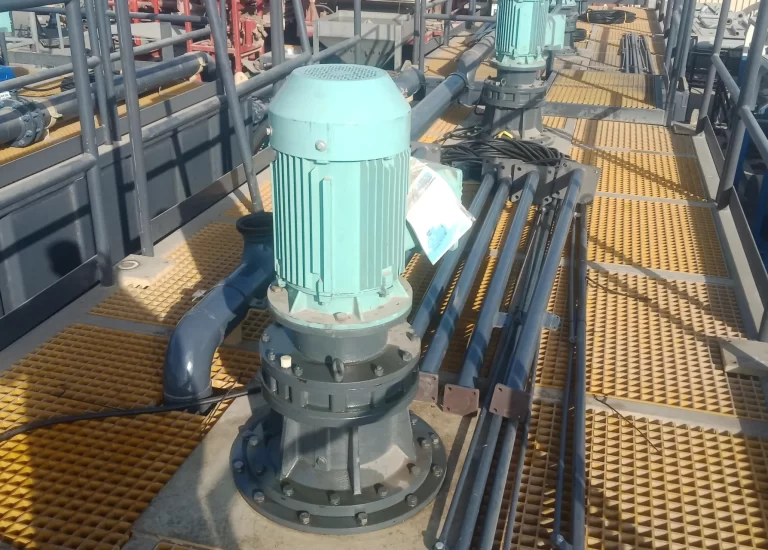

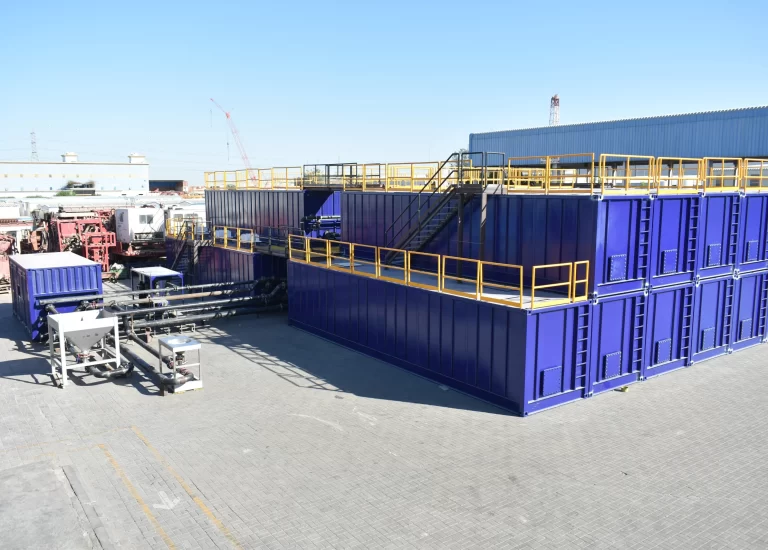

MSI FZC manufactures complete mud plants allowing the preparation of brine and oil based mud, the mixing, dry chemicals/salt adjunctions, recirculation, and storage.

MSI FZC LMPs are built in modules and the capacity can be easily increased or decreased for all the fluids (Base Oil, Brine, Oil Base Mud).

The plant is complete and includes all the hoppers with Venturi suction mixing jets, transfer pump for Base Oil, Mixing pumps (Carbon Steel and/or Stainless Steel) with manifold system for

Brine circulation and Mud circulation, Mud Mixing Tank, Brine Mixing Tank, Base Oil storage tanks, Brine Storage tanks and Oil Based Mud storage.

The plant has all necessary walkways, staircases, handrails and lighting system.

All the plant modules are built using standard seafreight containers footprints in order to avoid

extra shipping fees for oversized equipment transportation.

Previous

Next