cementing equipment

- Cementing Units

- Batch Mixer

- On-The-Fly Mixers

- Silos

- Cutting Bottle

- Dust Colllector

- Rock Catcher

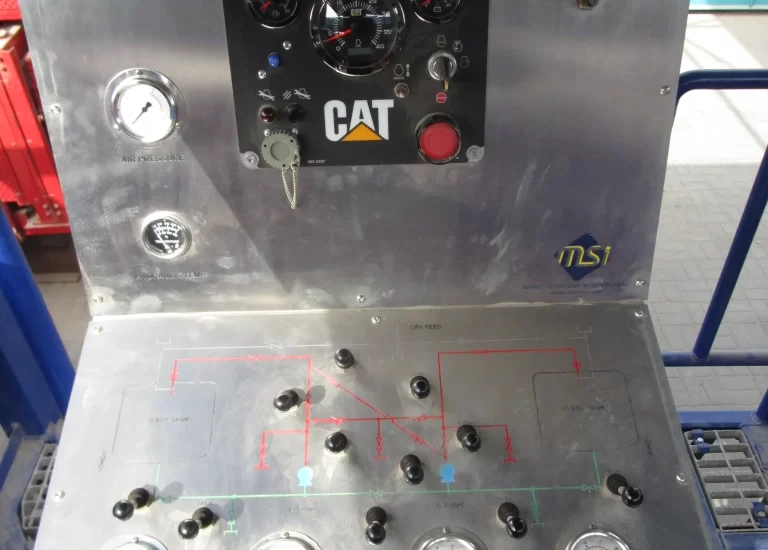

MSI FZC design and engineer cementing units according to the technical requirements of the clients and for various environment conditions, multi-regions standards, and transportation

modes.

As a result MSI FZC builds units on trailer, truck and skid either single skid or multiplex skid

system depending on site crane lifting capacities. The skid mounted units can be for onshore or

offshore operations. Rigsafe and ZONE 2 options are available.

The truck and trailer mounted units are built on vehicles in compliance with the local road &

transport authorities where they are intended to be registered. Units can be CE marked and

GOST certified.

HVAC systems can be installed in operator’s control cabins for summer operations and

Pre-Heating systems for winter operations can implemented.

MSI FZC can use any truck brand (MAN, SCANIA, IVECO, TATRA, MERCEDES, DAF, Renault,

NZKT, MAZ-MAN, VOLVO, KAMAZ, KENWORTH,…) in the design of the truck mounted units.

A wide variety of engines (Caterpillar, Detroit Diesel, MTU, Mercedes, Volvo Penta, Deutz,

Cummins,…) can be used and various transmissions too (Allison, Caterpillar, ZF,…).

MSI FZC can package any type/brand of plunger pumps (SPM, MSI, SERVA, GD, OFM,…) to

meet client’s requirements and main components (truck, deck engines, transmission and

pumps) can be either new or refurbished upon client’s request.

The MSI Cementing units can be equipped also with an Automatic Density Control System. All

units are equipped with Data Acquisition Systems and touchscreen interfaces.

Trading of Oil Field Equipments, Manufacturing of Manifolds and other Well service Equipment’s, High Pressure Fitting and Repair, Re-Manufacturing, Maintenance of valves and well service equipments.

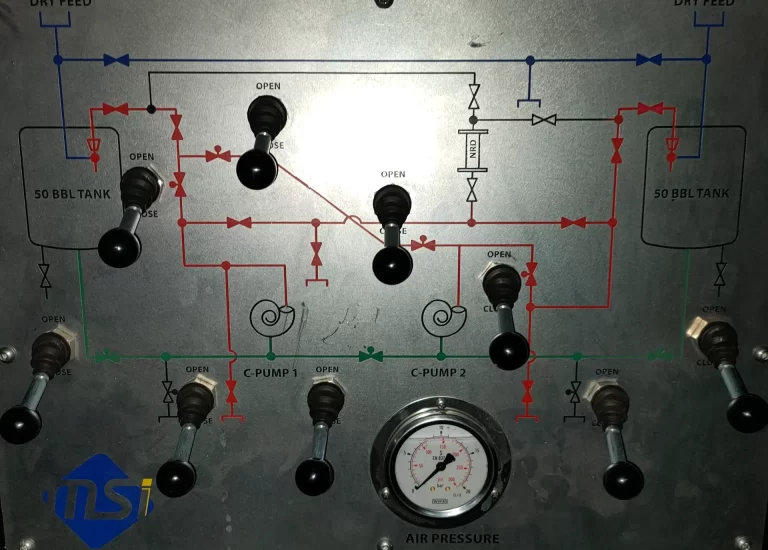

The capacity of the batch mixers range from 2x 50BBL up to 2x 125BBL or uneven split with

10m3 + 20m3. Tanks can have cylindrical shape or square shape with rounded corners and all

types have sloped/conical bottom and siphon system to prevent dead volumes.

The batch mixers can be equipped with non-roadioactive type Coriolis density meter, mixing

jets, recording systems and automatic density control upon request.

The batch mixers can be powered either by diesel engines and hydraulic motors or by electric

motors. Diesel engines can be of various brands and power depending on preference of the

clients. The electric motors are ATEX certified and all cables are armoured and equipped with

Eex glands.

The on-the-fly slurry mixers manufactured by MSI FZC can have various capacity and can either the “old-school” manual system also called “ground mixing system” or the more popular

standard one with 20BBL, equipped with a dry cement surge tank for steady cement delivery

and a mixing system allowing a 2.5 SG max density.

The power pack can be by diesel engine or electric motors.

The system can be equipped with an Automatic Density Control System upon request.

The On-The-Fly Mixers can by CE marked or GOST and can be made for onshore or offshore operations, desert or arctic operations. All specifications are customizable.